Recovering Antimony from Municipal Waste Incinerator Ash

Across Europe, municipal solid waste (MSW) incineration is an increasingly important part of waste management and energy production. In Denmark alone, roughly a quarter of all waste, over 3 million tonnes per year, is incinerated, producing valuable heat and electricity. However, this process also generates fly ash, a fine particulate residue that contains concentrated levels of potentially toxic metal(loid)s and is traditionally treated as a costly disposal problem.

Among these elements, antimony (Sb) stands out due to both its toxicity and technological importance. Sb is used in plastics, batteries, and flame retardants, and is now recognized as a Critical Raw Material (CRM) in the EU and USA. During waste incineration, Sb becomes highly enriched in fly ash — often reaching thousands of mg/kg, far exceeding the levels found in unburned waste. At the same time, these ashes also contain high concentrations of phosphorus (P), another CRM.

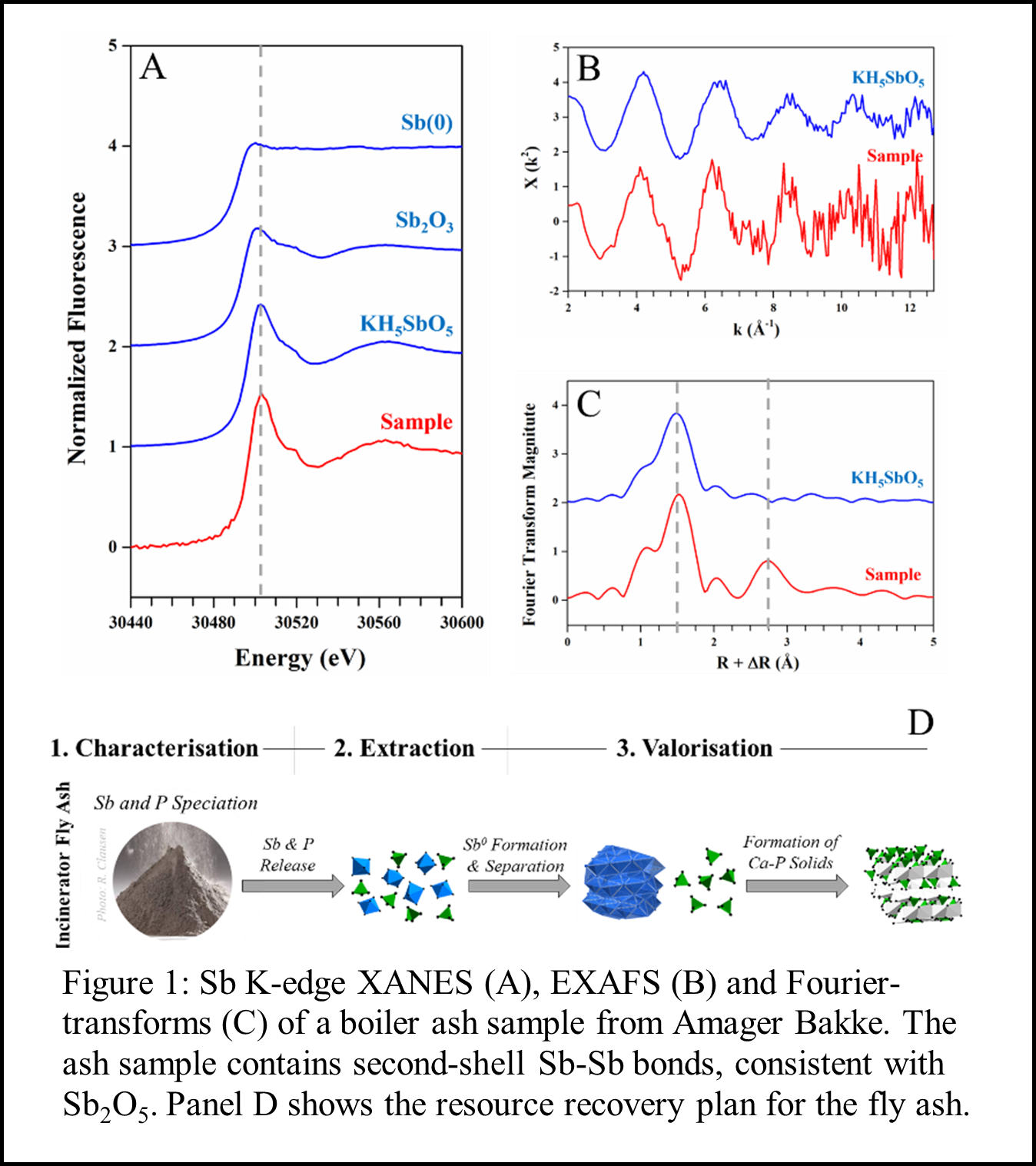

This project aims to transform this environmental challenge into an opportunity by developing methods to extract and recover Sb and P from incinerator ash. To achieve this, we combine macroscopic chemical analysis with synchrotron-based X-ray absorption spectroscopy (XAS) to determine the molecular-scale speciation of Sb throughout the incineration process. These measurements, performed at the Sb K-edge, provide crucial insight into how Sb is bound in different ash fractions and how they can be selectively extracted.

By linking chemical speciation to recovery potential, this project aims to guide the development of new extraction and valorization strategies that simultaneously reduce fly ash toxicity and generate valuable critical raw materials. In doing so, we aim to support a circular economy for metal(loid)s and contribute to the EU’s broader mission of resource independence and sustainable waste management.