Arsenic Treatment and Sludge Upcycling

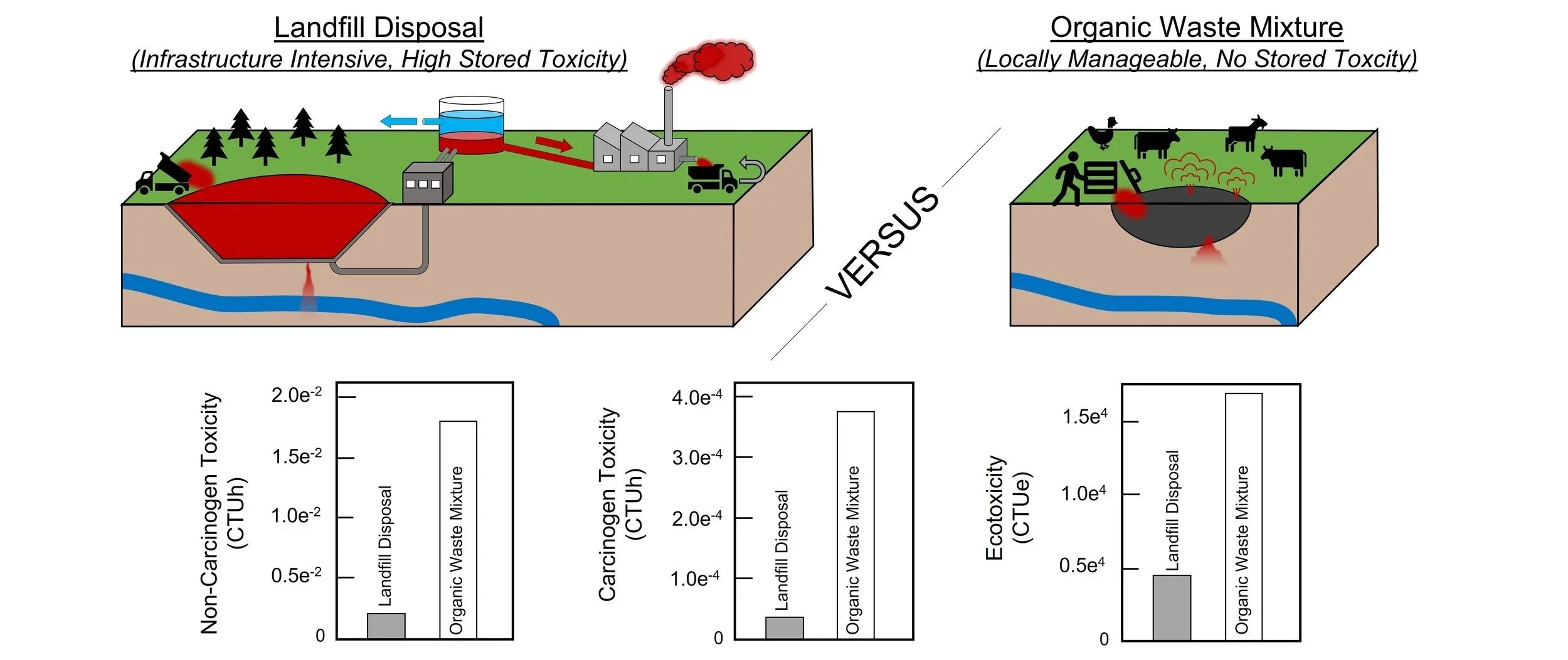

Arsenic (As) contamination of groundwater is a persistent global health challenge. Iron-based treatment methods effectively remove As but generate large volumes of arsenic-laden Fe(III) sludges, which are traditionally viewed as a disposal problem. Common strategies, such as landfilling or mixing with organic waste, can reduce immediate emissions but often store toxicity for future generations, highlighting the urgent need for recovery-oriented solutions.

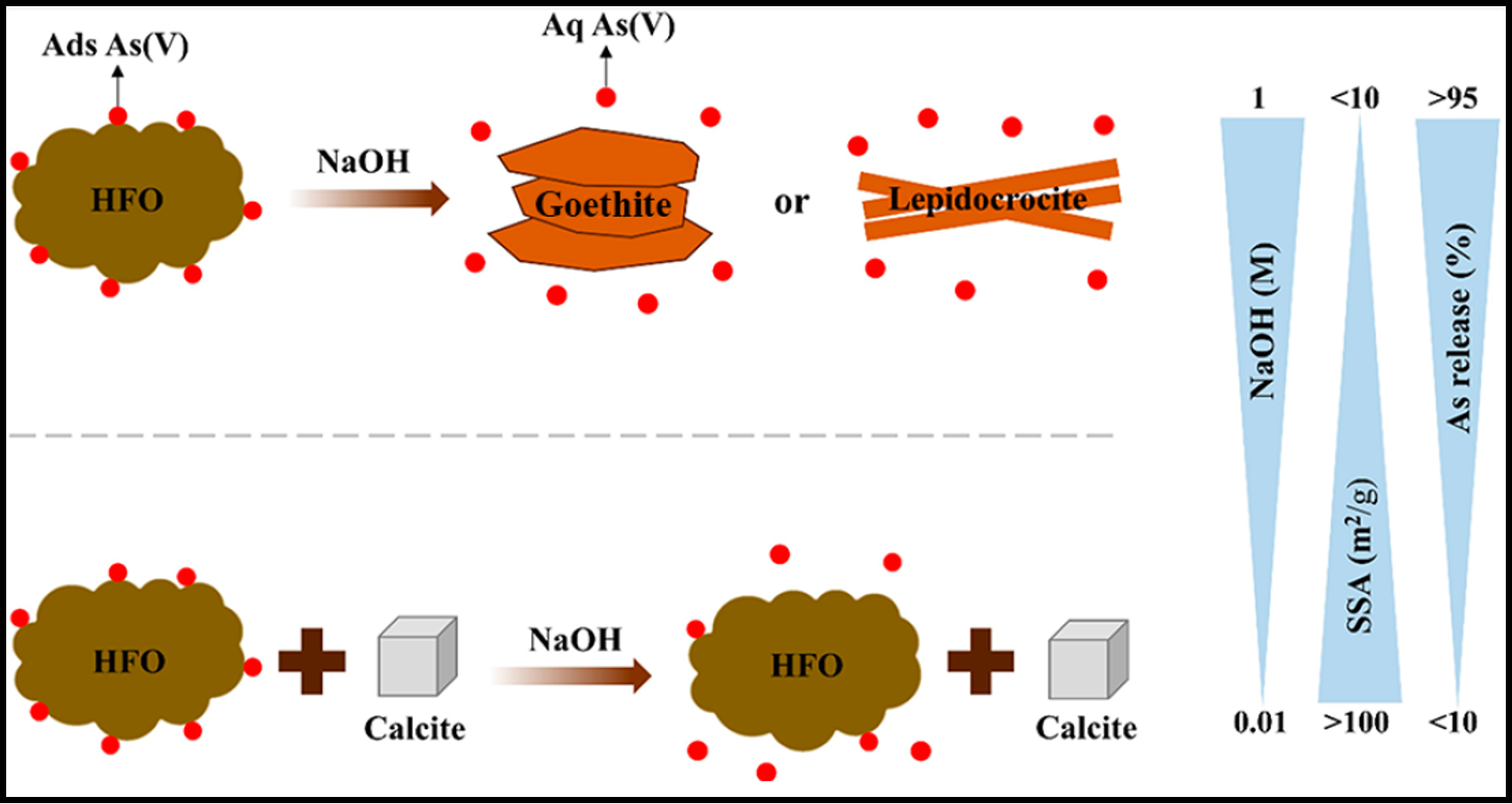

Our research addresses this challenge by treating arsenic-laden sludges as a resource rather than waste. Detailed characterization of sludges from various treatment plants around the world shows that they consistently contain nanoscale Fe(III) precipitates with high surface areas and arsenic bound predominantly as As(V), along with significant phosphate content. These structural similarities indicate that recovery methods can be broadly applied across diverse sludge sources.

We have developed alkali extraction strategies to efficiently separate As from sludge, achieving over 99% recovery under optimized conditions. Extraction alters the Fe(III) mineral structure and surface area but enables safe and effective arsenic removal, while the recovered material can be converted into metallic arsenic or phosphate products, both of which are classified as Critical Raw Materials.

Together, this project establishes a foundation for transforming a hazardous by-product of water treatment into a valuable source of critical materials. By combining molecular-scale characterization with practical extraction methods, we aim to reduce environmental and human health risks while closing the loop on resource recovery in water treatment systems.