Arsenic Recovery from Mining Waste

Decades of mining, ore roasting, and smelting have left a global legacy of arsenic (As) contamination, which poses severe environmental and human health challenges. Existing remediation strategies, such as vitrification, chemical stabilization, or underground freezing, are designed to immobilize As temporarily, not eliminate it. These approaches require permanent maintenance, passing the burden of risk and cost to future generations.

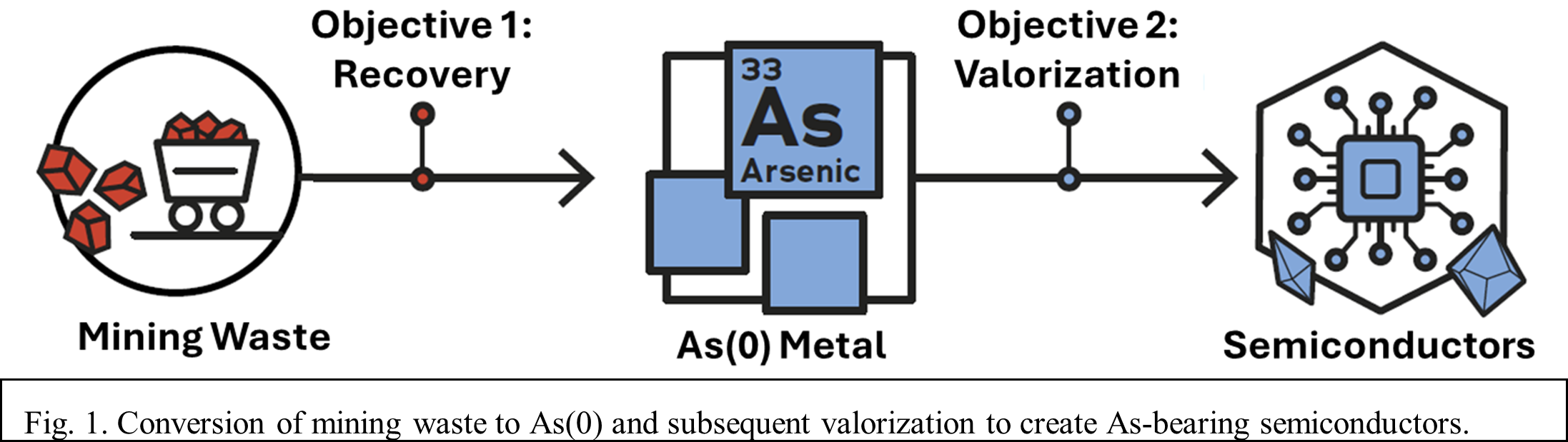

This research project aims to transform this narrative by reframing arsenic not as a waste problem, but as a valuable resource. With arsenic now classified as a Critical Raw Material (CRM) in the EU and USA due to its indispensable use in semiconductors, batteries, and clean energy technologies, new opportunities exist to recover As from legacy waste while reducing environmental hazards.

We are developing chemical upcycling methods to recover arsenic from contaminated mining materials and convert it into metallic arsenic [As(0)], a key feedstock for high-performance electronics. Building on this foundation, we are also exploring pathways to transform recovered As(0) into arsenene, a next-generation two-dimensional semiconductor material.

By coupling molecular-scale characterization with reactive process design, this work seeks to pioneer a circular approach to mining waste remediation. This novel approach both removes toxic legacy contaminants and creates critical materials for the energy transition. The vision is simple but profound: turn one of the world’s most persistent environmental liabilities into a sustainable resource for the future.